|

| Home | About Us | Resources | Products | Services | Contact US | |

| NANOLAB KNOWS THAT PROFITS ARE NOT MADE ON NANOTUBES ALONE | |

|

By Matt Kelly Small Times Correspondent |

Released:03/09/2004 |

|

NEWTON, Mass., March 9, 2004 - The simple strategy for technology businesses is to innovate or die. NanoLab Inc. takes that wisdom to heart, even in the fledgling world of carbon nanotubes.

The tiny spinout from Boston College formed four years ago to manufacture and sell carbon nanotubes. Revenues have risen nicely, from $191,500 in 2001 to nearly $675,000 last year. And, yes, the company does make a profit. Still, NanoLab's founders know that nanotubes eventually will be a high-volume, low-margin commodity business. So they relentlessly try to move upstream, developing more complicated structures: nanotweezers, nanowires, positioning equipment - whatever customers want and that they cannot find elsewhere. Exactly what those customers do with their nanotubes, "some we know, some we don't know," Carnahan said with a shrug. But NanoLab has seen increasingly precise requests for specific sizes and amounts of tubes, he added. "The sophistication of the buyer has improved tremendously." Girish Solanki, a Frost & Sullivan analyst who follows nanotech developments, agrees that nanotubes offer a long growth curve for shops like NanoLab. He estimates that more than 150 companies are considering nanotubes for composite materials alone. Solanki expects the worldwide demand for nanotubes to hit $600 million by 2010, or potentially much more if nagging large-scale manufacturing problems are solved. |

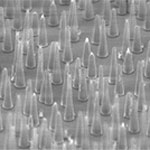

Photos courtesy of NanoLab Inc. David Carnahan, NanoLab's president Vital facts about NanoLab Inc.  Aligned carbon nanotubes are grown at NanoLab using a chemical vapor deposition process. The honeycomb pattern shown here was created by patterning the catalyst with a self-assembly lithography process. |

|

"People are looking at a lot of applications," Solanki says. "The thing is, they produce them in pilot-level

amounts."

NanoLab also does considerable work for the military. In November the company landed a $750,000 grant from the U.S. Army to continue research on how nanotubes can bolster the strength of body armor. The grant was awarded through the Soldier Systems Center in nearby Natick, Mass., which has worked with NanoLab for years. Michael Sennett, a research officer at the Soldier Center, said NanoLab has demonstrated "very promising" results so far by doping ceramics with nanotubes. The latest grant will let NanoLab make that material in larger amounts, which the Soldier Center will then place into body armor and test. NanoLab is actually one of two startups working with the Soldier Center on body armor; the other is MER Corp. in Tucson, Ariz. "They both stood out for their technical expertise and both demonstrated expertise in synthesizing the tubes, which is no easy task," Sennett said. NanoLab can currently make as much as 100 grams of nanotubes per day. Carnahan expects that volume to rise to 1 kilogram soon with some newly purchased equipment. He does not, however, feel threatened by the countless potential rivals striving to make nanotubes in large volume - thus making it a low-profit product. Rather than supply tubes as a commodity, Carnahan hopes to promote that machine-shop image: a small, skillful supplier that delivers tubes with a customer's desired morphology. "There's always going to be a customer who knows exactly what he needs," he said. Company file: NanoLab Inc. (last updated March 8, 2004) Company NanoLab Inc. Headquarters 55 Chapel St. Newton MA 02458 History Incorporated in January 2000, NanoLab is a Boston College spinoff that has its origins in research conducted by Dr. Zhifeng Ren at SUNY-Buffalo before his 1999 move to Boston College. Employees 8 Small tech-related products and services Using a chemical-vapor deposition process licensed from Boston College, NanoLab has become a major US manufacturer and supplier of multiwall carbon nanotubes, aligned arrays of carbon nanotubes on substrates, nanoparticles and nanowires. Financials Approximately 25 percent of 2003 corporate revenues derived from sales, with 75 percent stemming from R&D-related income, including an Army-funded SBIR Phase II grant. Selected customers and strategic partners Selected competitors Barriers to market Though prices on raw materials for nanotechnology are already dropping, it will be some time before materials developed using nanotech processes are truly affordable. The large number of competitors in this crowded niche is leading nanotubes toward a likely status as a low-profit product. Fortunately, buying patterns indicate that customers are becoming savvy about what types and amounts of carbon nanotubes they require. This could mesh well with NanoLab's aspiration to provide customized nanotubes, rather than large-volume batches. Contact URL: http://www.nano- lab.com/ Phone: 617-581-6747 Fax: 617-581-6749 E-mail: info@nano-lab.com -Research by Gretchen McNeely Original Article on Small Times | |